Key Takeaways

1. Choosing the right loading dock doors directly impacts safety, efficiency, and cost control.

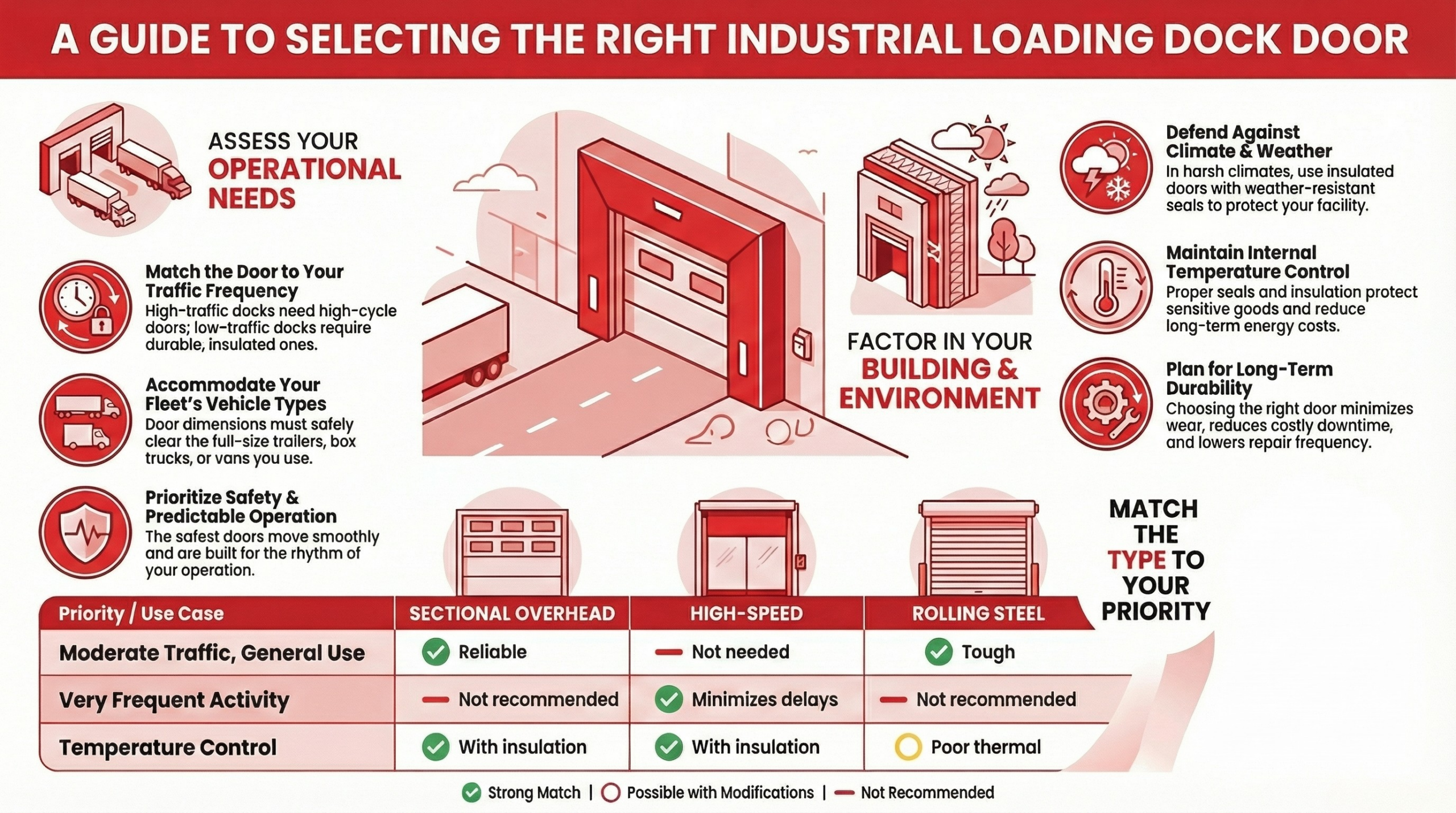

2. When selecting a dock door, consider factors such as usage frequency, vehicle types, climate, temperature control, and safety risks.

3. Anchor Doors helps business owners select, install, and maintain dock doors that fit their building, garage, workflow, and future needs.

7 Factors To Consider When Choosing the Right Loading Dock Doors

Choosing loading dock doors works best when decisions are tied directly to how the dock operates, the building environment, and long-term performance needs. Based on standard dock equipment considerations, these seven factors typically shape the right choice.

1. Dock Usage and Traffic Frequency

The first thing to understand about a loading dock is how hard it works during a typical day. Some docks see steady movement from morning to evening, with trucks arriving back-to-back and doors opening and closing dozens, sometimes hundreds, of times.

Others are used only a few times a day, with longer gaps between deliveries. That difference in traffic plays a major role in choosing the right dock doors.

A simple example is a distribution center versus a small warehouse. A distribution center with trucks arriving every 10 to 15 minutes should choose high-cycle dock doors built for continuous operation.

A warehouse with scheduled deliveries once or twice a day can choose insulated, heavy-duty doors that focus on energy efficiency and long-term reliability. Making this choice early helps align the door’s design with how the dock actually functions.

2. Vehicle Types and Dock Clearance

Once you understand how often the dock is used, the next decision point is what is pulling up to it. Loading dock doors need to accommodate the real vehicles your operation sees every day, not an idealized standard size.

Vehicle dimensions, turning radius, and loading height all influence which doors will work safely and efficiently. Different vehicle types place different demands on dock openings.

- Full-size trailers typically require taller and wider doors with precise alignment to prevent gaps during loading.

- Box trucks often vary in height and may require more flexible clearance to accommodate mixed fleets.

- Smaller delivery vans, while easier to accommodate, still require consistent door positioning to avoid awkward loading angles that slow down work or strain equipment.

3. Climate and Weather Exposure

Climate is one of the most overlooked factors when choosing loading dock doors, yet it has a direct and lasting impact on a facility’s performance. Every time a dock door opens, it creates an exchange between indoor and outdoor conditions.

The harsher or more unpredictable the weather, the more important it becomes to choose doors designed to manage that exposure. In regions with strong winds, heavy rain, or snow, dock doors need more than basic panels.

Temperature swings introduce another layer of complexity. Facilities that operate in cold winters or hot summers experience constant thermal stress at the dock.

Choosing insulated doors with weather-resistant seals helps stabilize indoor conditions, protect products, and reduce long-term energy strain.

4. Temperature Control Inside the Facility

Temperature control is not limited to what happens inside the warehouse walls. Every time a dock door opens, you are briefly inviting the outside in.

If the door is not insulated or does not seal well, that invitation lasts much longer than it should. In buildings that store temperature-sensitive products or maintain controlled workspaces, those small gaps add up.

Cold air escapes in winter, heat and humidity creep in during summer, and HVAC systems work harder to compensate. Over time, this shows up in higher energy bills, inconsistent temperatures, and uncomfortable working conditions near the dock.

Hence, choose doors designed to maintain temperature to help protect products and keep the rest of the building from paying the price.

5. Safety and Operational Risk

Loading docks move fast, and doors need to keep up without becoming a hazard. When doors are not suited to the pace of the dock, they tend to get in the way.

Slow movement, poor visibility, or unpredictable operations increase the risk of impacts, near misses, and equipment damage. The safest dock doors are the ones that feel predictable.

They open and close smoothly, give operators clear sightlines, and behave the same way every time. When doors are mismatched to the environment, workers adapt by working around them, which is usually when accidents happen.

Hence, choose a door that is built for the speed and rhythm of the operation, which helps keep people focused on their work instead of avoiding obstacles.

6. Integration With Dock Equipment

Dock doors are only one piece of a larger system. They need to work alongside levelers, seals, and shelters, not fight against them. When these components are mismatched, small inefficiencies begin to accumulate.

Gaps around the door let air and moisture through. Misalignment puts extra stress on hardware. Over time, those issues lead to faster wear and more frequent repairs. None of this happens all at once, which is why it is easy to miss during the planning stage.

Choosing doors with the full dock system in mind helps everything function as a single unit rather than as separate pieces.

7. Maintenance Demands and Long-Term Durability

Every dock door will need service eventually. The real question is how often and how disruptive that service will be. Doors that are chosen without considering usage tend to break down more frequently and at the worst possible times.

- High-traffic docks benefit from doors built to handle constant movement without excessive wear.

- Lower-use docks still need quality construction, but the emphasis shifts toward long-term reliability rather than speed.

In both cases, access to local service and parts makes a noticeable difference when something goes wrong. Make sure to choose the door that offers fewer interruptions, less downtime, and a system that does its job for years without demanding attention.

Common Types of Loading Dock Doors You Can Get

There are different types of loading dock doors you can choose from, and each style depends on how your dock operates day to day. The types of doors address specific challenges, from heavy traffic and security needs to temperature control and space limitations.

Let’s take a look at them:

- Sectional overhead dock doors. These doors open vertically and rest along the ceiling, making them a versatile choice for many facilities. They offer good insulation options and work well for moderate-to-high dock traffic.

- Rolling steel dock doors. Built for durability and security, rolling steel doors coil into a compact roll above the opening. They are well-suited for industrial environments where space and protection are top priorities.

- High-speed fabric or rubber doors. Designed for fast-paced operations, these doors open and close quickly to reduce air exchange and bottlenecks. They are often used in facilities where efficiency and temperature control matter most.

- Insulated dock doors. These doors are built with thermal performance in mind, helping maintain interior temperatures during frequent loading cycles. They are ideal for climate-controlled buildings and energy-conscious operations.

- Impact-resistant dock doors. Constructed to withstand repeated contact from forklifts or carts, these doors reduce downtime caused by accidental impacts. They are a practical option for busy docks where collisions are hard to avoid.

This table is intended as a starting guide. Your facility’s daily routines, building structure, and long-term goals play an important role in the final selection. Visit Anchor Doors & Service Inc., where you’ll meet experienced professionals who can assess your facility’s needs and recommend the best solution.

| Use Case / Priority | Sectional Overhead | High-Speed/High-Performance | Rolling Steel | Insulated Doors | Fold-Up / Folding Doors |

|---|---|---|---|---|---|

| Moderate traffic, general use | ✔ Reliable & cost-effective | — Not necessary | ✔ Tough & low-maintenance | Optional | — |

| Very frequent dock activity | — | ✔ Minimizes air exchange & delays | — | Optional | — |

| Exposure to impact or harsh conditions | ✔ Can be reinforced | ❍ Moderate | ✔ Excellent durability | ❍ Optional | — |

| Temperature control important | ✔ With insulation | ✔ With insulation | ❍ Poor thermal | ✔ Best choice | ✔ With insulation |

| Limited overhead space | ❍ Needs tracks | — | ✔ Compact coil | ❍ Needs space | ✔ Ideal |

Legend: ✔ Strong match | ❍ Possible with modifications | — Not recommended

Why Choosing the Right Loading Dock Doors Matters for Your Business

Loading dock doors sit at the intersection of people, equipment, and building infrastructure. When they are properly selected, daily operations move smoothly. When they are not, small inefficiencies tend to compound into safety risks, delays, and rising maintenance costs.

Here’s why it matters:

- Keeps daily operations moving smoothly by supporting efficient loading and unloading without unnecessary delays.

- Improves worker safety by reducing the risk of sudden door failures, impact damage, and uncontrolled movement.

- Limits liability exposure by creating a safer, more predictable dock environment for employees and drivers.

- Maintains energy efficiency through proper sealing and insulation, which helps control indoor temperatures.

- Protects stored goods from exposure to weather, moisture, and temperature fluctuations.

- Reduces wear on dock equipment by matching the door design to traffic levels and operating demands.

- Preserves the building structure by minimizing stress on tracks, openers, and surrounding dock areas.

- Lowers long-term operating costs by decreasing repairs, downtime, and energy loss over time.

A Practical Path Forward With Anchor Doors & Service Inc.

Loading docks play a bigger role in building safety and efficiency than most people realize. According to the U.S. Occupational Safety and Health Administration (OSHA), loading docks are among the most injury-prone areas in industrial facilities due to vehicle movement, heavy equipment, and door-related hazards.

When you choose dock doors without fully considering usage, climate, safety, and system compatibility, the impact shows up over time. Making the right choice upfront helps protect people, products, and the building itself.

What to Do Next

- Take a closer look at how your dock actually operates, including traffic volume, vehicle types, and environmental exposure.

- Identify where inefficiencies or risks may already exist, such as energy loss, frequent repairs, or safety concerns.

- Work with Anchor Doors & Service Inc. to assess your building and receive solution-focused guidance tailored to your home or business.

With over 20 years of local experience across Windsor & Essex County, Chatham-Kent, and surrounding communities, Anchor Doors & Service Inc. combines technical expertise with dependable service.

If you are planning a new installation, upgrade, or repair, contact Anchor Doors & Service Inc. today to get clear guidance and honest recommendations.

FAQs

Loading dock doors are typically constructed from steel, aluminum, or composite materials, with many models offering insulated cores. Insulation helps regulate indoor temperatures and supports energy efficiency in busy facilities.

While sizes vary by building and vehicle type, a common industry standard is around 8 feet wide by 9 feet high. Final dimensions should always reflect the vehicles, loads, and clearance your dock handles daily.

OSHA requires fall protection at loading docks where there is a drop of four feet or more, as outlined in 29 CFR 1910.28(b)(1)(i). Barriers such as dock safety bars or guardrails are commonly used to meet this requirement and reduce the risk of falls.